Within production automation, we ensure that a unit of equipment is integrated to perform specific production tasks on its own.

Robotics workstations handling technological processes enhance the precision and repeatability of operations, leading to improved product quality and a reduction in manufacturing waste.

Comprehensive packaging lines enable fast, precise, and uniform packaging of products, enhancing their appeal to customers and reducing the risk of damage during transport.

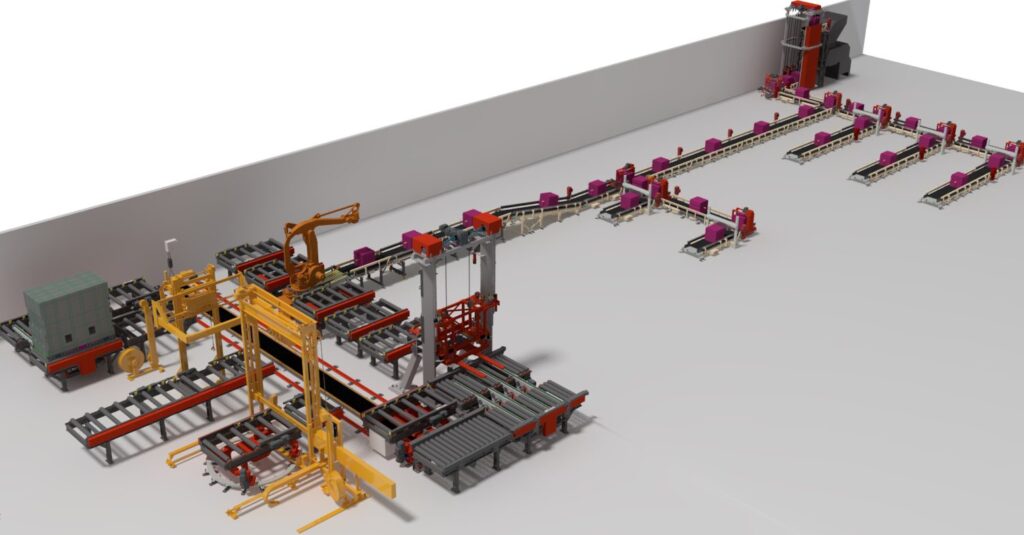

The project aimed to automate the process of packaging and transporting materials within a manufacturing company to increase efficiency, reduce processing time, and minimize the risk of production line downtime.

Self-loading and unloading trailers significantly expedite logistics processes, reduce the need for manual intervention by workers, and decrease the risk of errors during cargo handling.

The project aimed to create a transport system that would enable the transportation of engine blocks from the casting machine without the use of traditional pallets.

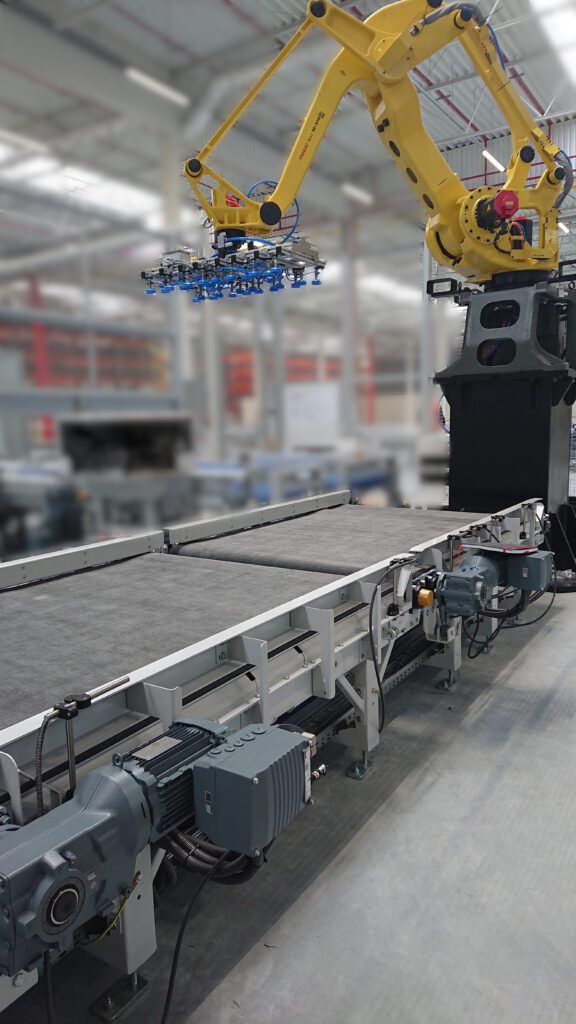

Automated palletizing systems are technologically advanced solutions designed for the precise and automated arrangement of products on pallets. They enable fast and efficient preparation of loads for transportation or storage, while minimizing the risk of human errors. Widely used in distribution centers, warehouses, and manufacturing facilities, these systems provide high throughput and accuracy in goods handling.

Specifications:

– Capability to stack 2 pallets or more,

– Adjustable height of the pallet stack as needed,

– Forklift capacity up to 1200 kg,

– Operating cycle of the stacker approximately 70 seconds.

Automated order fulfillment systems are advanced technological solutions comprising robots, algorithms, and tracking technologies. They are used for the collection, sorting, and preparation of products for shipment across various industries. These systems provide efficient ways to automate warehouse processes, especially in scenarios where precision and speed in order fulfillment are essential.

Risk analysis enables early detection of potential threats in the production process, allowing for proactive measures to prevent downtime, minimize losses, and ensure the safety of both workers and equipment.

Feel free to contact us by phone or email. Our staff will be happy to answer your questions.

The evolving technologies and requirements for the parameters of manufactured structural elements drive us to continually upgrade our technical infrastructure with the latest equipment. High-quality machines enable us to achieve perfect results in production, translating into the high quality and durability of the devices we manufacture.

Headquarters:

PROMUS Katowice Sp. z o.o.

ul. Społeczna 8A

PL 41-214 Sosnowiec

Office:

PROMUS Katowice, organizačni slożka

ul. Průmyslova 830

CZ 293-06 Kosmonosy

© All Rights Reserved.